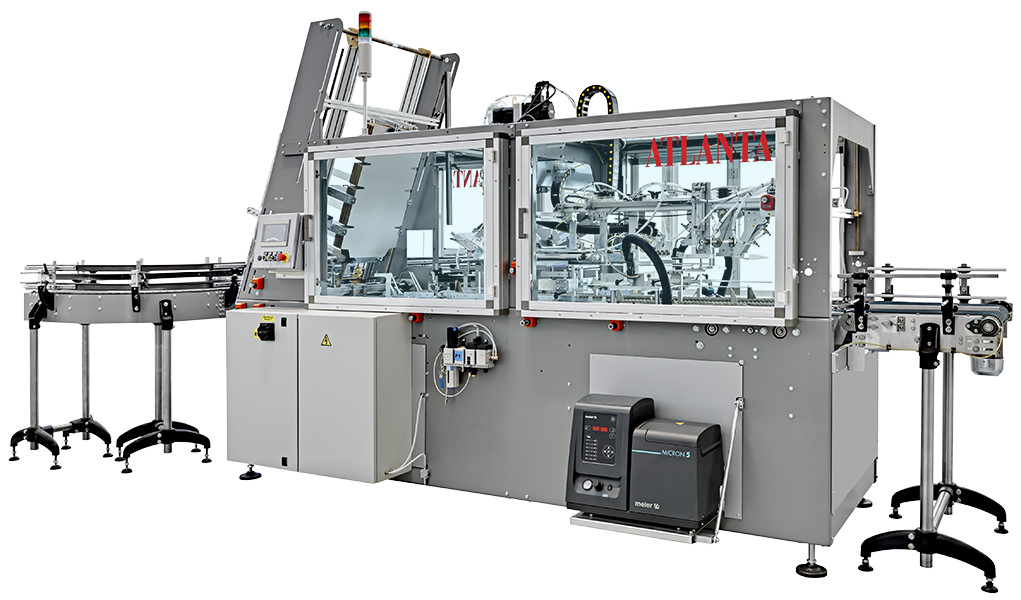

Compact cartoning machines particularly suited for production lines requiring a small machine with a speed of up to 15 blanks per minute.

The precision with which the box is wrapped around the product to create neat, stackable and environmentally-friendly packs is the reason why it is used in multiple industrial sectors:

Quality in less than 4 metres; easy to introduce even in lines that are already up and running and with minimum space.

TCO (Total Cost of Ownership) is low, with top-of-the-range performance.

“Inserter” device for additional product protection during handling operations.

Precision Pick&Place unit to stack products over several layers.

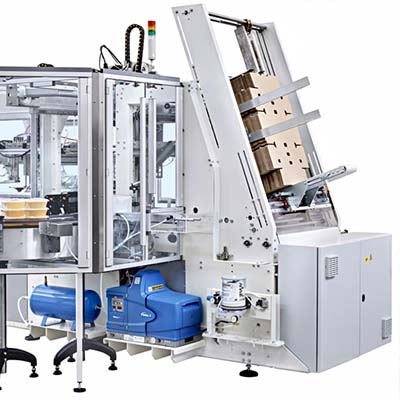

Raised magazine to facilitate refilling the blanks with a capacity of between 200 and 400 pieces.

The machine architecture is designed to facilitate inspection and speed up maintenance tasks.

The accuracy in positioning small or large products makes the Raffaello Series the optimal choice to protect products with an environmentally-friendly, hard-wearing and easily stackable pack.

The Raffaello ultra compact wrap-around cartoning machines form the box around the product starting from a flat blank. This ensures maximum stability of the product within the carton.

It is recommended for packing:

The Raffaello P&P model is fitted with a Pick&Place system to create packs that contain up to 4 product layers; the maximum number of layers depends on the height and design of the packaging. The picking system takes the product, either loose or pre-bundled, and places it on the carton in stacked layers.

Raffaello P&P is supplied with the most suitable picking system for the product to be stacked. The gripping unit with picking arm can be:

If you want an automatic machine for end of line packaging that’s cost-effective yet without compromise, Raffaello is the perfect solution.

Indeed, this cartoning machine has an extremely beneficial total cost of ownership owing to the modularity of its components, the optimisation of the mechanics and the easy maintenance that minimises machine downtime and operator tasks.

The pick-up, positioning and folding system is designed to be effective even with not perfectly flat blanks and is suitable for both normal logistic packaging and high-quality packaging:

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

With Raffaello cartoning machines, you can pack your products in wrap around boxes and trays on one or more layers.

4 standard models that can quickly be tailored for maximum production efficiency

Packaging: Wrap-around or Tray

Dimensions: 3,800 x 3,500 x 2,500 mm (LxWxH)

Speed: 15 cartons/minute

Feeding: 90°

Separation: Pusher

Magazine, Capacity: 200, Possibility of extension (optional) 400

Packaging: Wrap-around or Tray with product in 1 or more layers

Dimensions: 3,800 x 3,500 x 2,500 mm (LxWxH)

Speed: 15 cartons/minute (single layer)

Feeding: In-line (4 channels) or at 90° optional; Anti-jamming unit

Separation: Pusher if 90°

Magazine, Capacity: 200, Possibility of extension (optional) 400

Packaging: Wrap-around or Tray with product in 1 or more layers

Dimensions: 4,300 x 2,200 x 2,500 mm (LxWxH)

Speed: 15 cartons/minute (single layer)

Feeding: In-line (4 channels) or at 90° optional; Anti-jamming unit

Separation: Transfer unit

Magazine, Capacity: 200, Possibility of extension (optional) 400

Packaging: Wrap-around or Tray with product in 1 or more layers

Dimensions: 4,300 x 2,200 x 2,500 mm (LxWxH)

Speed: 15 cartons/minute

Feeding: In-line (4 channels); Anti-jamming unit

Separation: Transfer unit

Magazine, Capacity: 200, Possibility of extension (optional) 400

Maximum attention to safety. Each moving part is protected to ensure the safety of line operators.

Sliding safety guards allow the operator to have full view of the machine, the wide opening ensures easy access during maintenance and cleaning.

Machine designed to operate over three shifts, with low energy consumption and silently.

Touch screen panel with simple and intuitive interface: this allows the operator to quickly set all parameters and has a broad range of pre-sets.

Pick&Place module available with different versions, including magnetic, suction cups and vanes.

Quick format changeover pre-set that can be activated from the standard touch screen control panel.

Combined blank and product detection with sensors and photocells.

Production speed up to 15 cartons/trays per minute

Blank thickness 2 to 5 mm

Upper flap closure internal

Installed power 13 kW

Voltage 400V – 3-Phase/50Hz + N + G

Electrical protection IP54

Compressed air consumption 400 NI at 6 bar

Operating temperature min +5°C – max +40°C

Relative humidity max 70%

Total weight 2,500 kg

Product presence check feelers + photocells

Machine colour RAL 7037 (gray)

Partial automatic format changeover

Additional channels

Inserter device unit

Separating sheet inserter for multi-layer packages

Adjustable feeding guides with handwheels

Manual or automatic centralized lubrication

Motorized crossover infeed conveyor

Photocells for product presence check after separation phase

External upper flap closure

Customized RAL colour

Electrical panel air conditioning

Interface with host computer for data transfer

Teleassistance

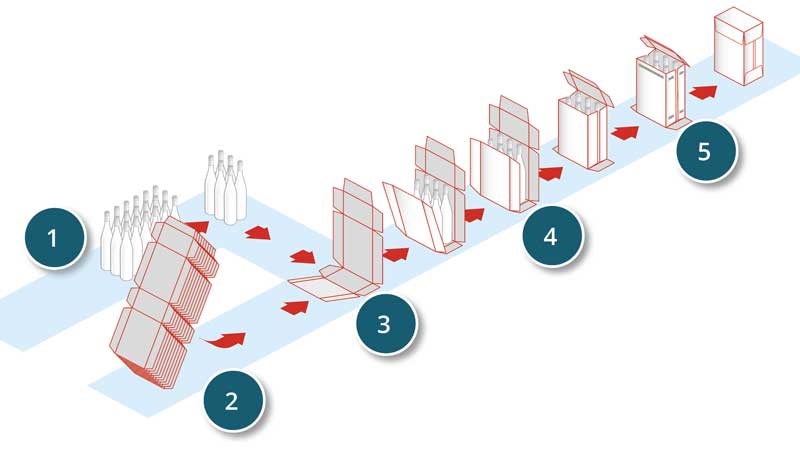

1- Loose products can arrive in-line (also through a crossover infeed conveyor) or at 90°.

2- The blank is taken from the magazine by a suction cup system.

3- The first fold prepares the blank to receive the group of products.

4- The box is formed around the product with consecutive folds, while passing along the production line.

5- Glued points are applied and the flap can be internal (standard) or external (optional).

Watch the Raffaello series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Product infeed designed specifically to decrease the product channelling space with respect to the line of frozen products.

Product type: food trays

Formats: 2×1 on 3 layers

The company decided to equip its end of line with an automatic machine to pack its food products packed in trays. The line layout and the product characteristics presented non-standard characteristics:

Cement sacks in wrap around pack with different configurations.

How to pack heavy products packed in sacks in wrap around boxes. This type of pack posed several problems during wrapping, including:

The weight of the product

The lack of compactness of each individual pack

There was a considerable difference in texture as the format changed

The top of the sack had to be folded accurately before being wrapped by the cardboard.

POWERED BY

Atlanta S.p.A.

Via Europa n.13

40010 Sala Bolognese (Bo) Italy

T. +39 051 722792

SDI M5UXCR1

Tax code and VAT reg. no. 02144141203

Share capital € 1.000.000,00 i.v

REA 416021

Registration date REA: 09/02/2001