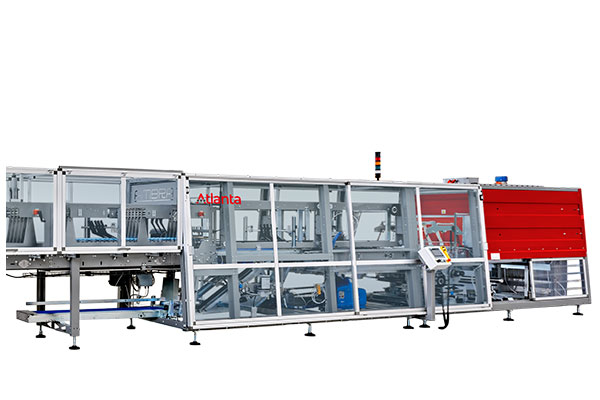

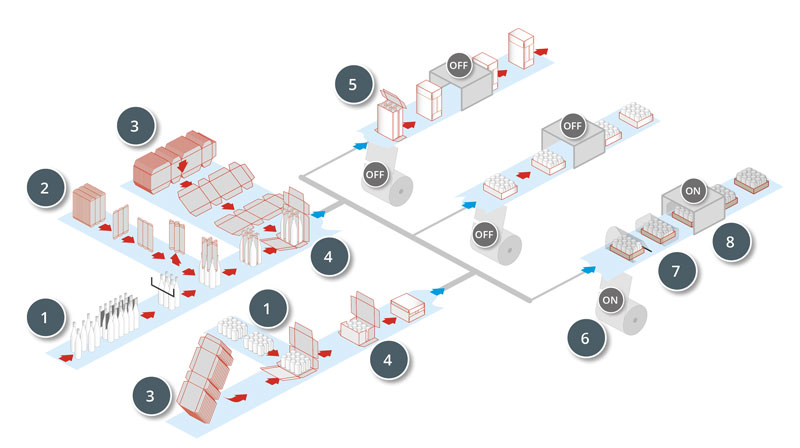

This series of packaging machines brings together the benefits of wrap around technology with those of shrink-wrap machines in a single machine.

The P&P pick-and-place model positions several product layers in a single box. The gripping unit can be mechanical, magnetic or with suction cups.

The“inserter”arm picks using suction cups that accurately positions the flat pad or opens the inserter according to need.

The modular structure of these packaging machines makes it possible to tailor each model, making it unique and perfectly suited to your line.

The various optionals make it possible to have a machine with a superior level of automation, to minimise line operator intervention.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Wrap-around box; tray, octagonal tray; tray plus film, octagonal tray plus film.

12 standard models and an extensive range of optionals to tailor your model

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 8,000 x 3,500 x 2,500 mm (LxWxH)

Speed packages/minute: Single lane: 15

Feeding: 90°

Separation: Pusher

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Sealing bar

Packaging: Tray, Tray + film, Wrap-around

Dimensioni: 8,400 x 2,200 x 2,500 mm (LxWxH)

Speed packages/minute: Single lane: 15

Feeding: In-line (4 channels), Anti-jamming unit

Separation: Transfer unit

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Sealing bar

Packaging: Tray, Tray + film, Wrap-around

Dimensions: In-line 8,400 x 2,200 x 2,500 mm – 90° 8,000 x 3,500 x 2,500 (LxWxH)

Speed packages/minute: Single lane: 15single layer

Feeding: In-line (4 channels), 90°optional, Anti-jamming unit

Separation: Transfer unit, Pusherif 90°

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Sealing bar

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 10,600 x 3,500 x 2,500 mm (LxWxH)

Speed packages/minute: Single lane: 15

Feeding: 90°

Separation: Pusher

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 11,000 x 2,200 x 2,500 mm (LxWxH)

Speed packages/minute: Single lane: 15

Feeding: In-line (4 channels), Anti-jamming unit

Separation: Transfer unit

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensioni: In-line 11,000 x 2,200 x 2,500 mm – 90° 10,600 x 3,500 x 2,500 mm (LxWxH)

Speed packages/minute: Single lane: 15single layer

Feeding: In-line (4 channels), 90°optional, Anti-jamming unit

Separation: Transfer unit, Pusherif 90°

Magazine: Capacity: 200, Possibility of extension optional 400

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 11,000 x 2,345 x 2,200 mm(LxWxH)

Speed packages/minute: Single lane: 25

Feeding: In-line (4 channels), 90°optional, Anti-jamming unit

Separation: Transfer unit

Magazine capacity: 300, Possibility of extension optional 500

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 10,680 x 5,380 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane: 25

Feeding: 90°

Separation: Pusher

Magazine capacity: 300, Possibility of extension optional 500

Bundling machine: Film launch

Packaging: Pad + Film

Dimensions: 8,102 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 25, Double lane (function can be activated in film only mode): 50, Triple lane (function can be activated in film only mode): 75

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 12,280 x 3,000 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane: 40

Feeding: In-line (4 channels), 90°optional, Anti-jamming unit

Separation: Transfer unit

Magazine Capacity: 250

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 13,575 x 3,950 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane: 45

Feeding: In-line (4 channels), 90°optional, Anti-jamming unit

Separation: Transfer unit

Magazine: Capacity: 300, Possibility of extension optional 600

Bundling machine: Film launch

Packaging: Tray, Tray + film, Wrap-around

Dimensions: 18,600 x 5,200 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane: 50

Feeding: In-line (4 channels), Anti-jamming unit

Separation: Continuous

Magazine: Capacity: 300, Possibility of extension optional 600

Bundling machine: Film launch

Movements activated by high efficiency brushless and asynchronous motors.

Sliding safety guards allow the operator to have full view of the machine, the wide opening ensures easy access during maintenance and cleaning.

High-efficiency heat-shrink tunnel with pre-chamber to prevent dissipation of heat and air flow control module to control turbulence.

Touch screen panel with simple and intuitive interface: this allows the operator to quickly set all parameters.

Quick format changeover through the standard touch screen control panel; it normally does not require replacing parts.

Automatic format changeover available as optional. High precision centring of the printed film.

High precision centering of the printed film.

Combined product presence control in the channels, both with feelers and with photocells.

Blank feeding with suction cup system.

Cutting blade length: 650 mm

Installed power: 45 kw – 100 kw

Voltage: 400V – 3 Phase / 50 Hz + N + G

Electrical protection: IP54

Compressed air consumption: 400 NI/ciclo a 6 bar

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Total weight: 4,000 kg – 5,300 kg

Machine colour: RAL 7037 (gray), RAL 3020 (red)

Automatic format changeover

External upper flap closure

1/4 pallet tray

Inserter device unit

Extended magazine

Pick & Place unit

Manual or automatic centralized lubrication

Photocells for product presence check after separation phase

Partial stainless steel version

4.0 Industry

Teleassistance

Automatic reel replacement

Additional channels

Printed film

Adjustable feeding guides with handwheels

Motorized crossover infeed conveyor

Pneumatic motor to empty oven in case of power shut off

Customized RAL colour

Electrical panel air conditioning

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

POWERED BY

Atlanta S.p.A.

Via Europa n.13

40010 Sala Bolognese (Bo) Italy

T. +39 051 722792

SDI M5UXCR1

Tax code and VAT reg. no. 02144141203

Share capital € 1.000.000,00 i.v

REA 416021

Registration date REA: 09/02/2001