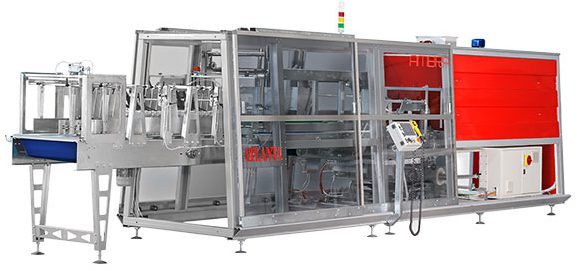

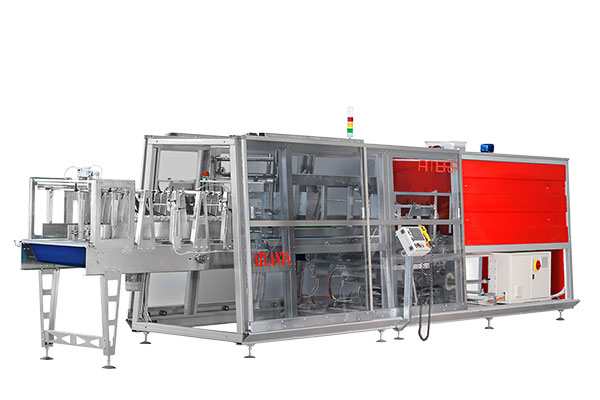

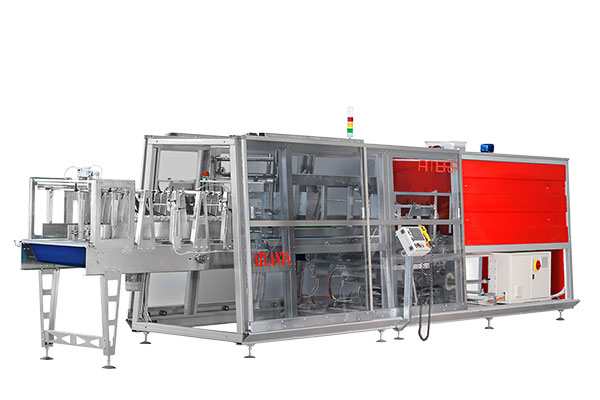

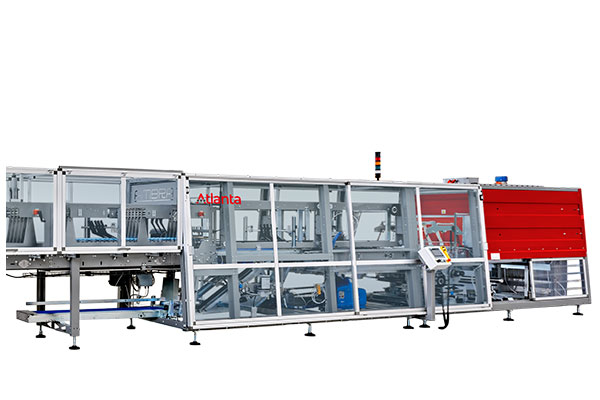

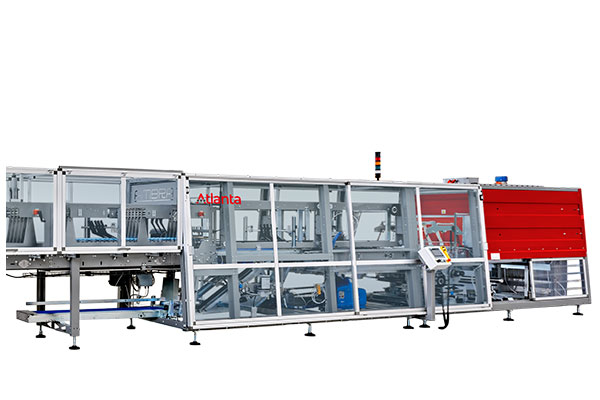

Reliable and easy-to-use entry-level automatic packaging machine with film feeder for production of up to 1,800 packs per hour. Its extremely compact size and simple format changeover make it ideal for the beverage, food, detergent and personal care sectors.

minimal maintenance time and costs make it an optimal choice.

the machine architecture is designed to facilitate inspection, accelerate maintenance and oven emptying.

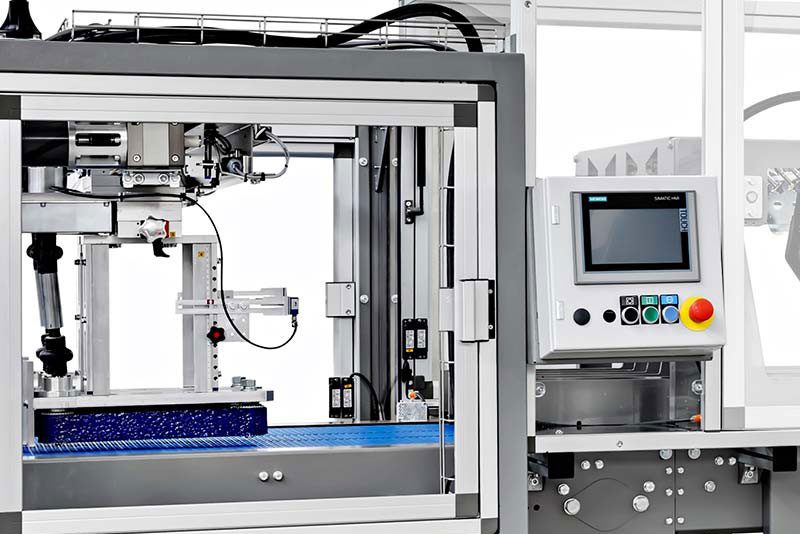

The entire packaging cycle is monitored by a series of mechanical and optic sensors that control the product in transit.

Easy to use, this shrink-wrap machine requires minimal maintenance and makes it possible to replace the reel and refill the magazine in just a few minutes.

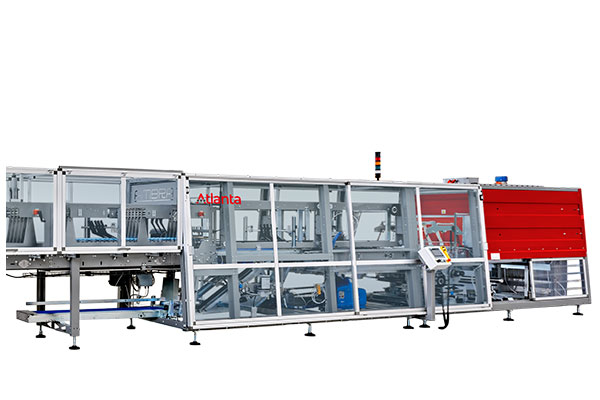

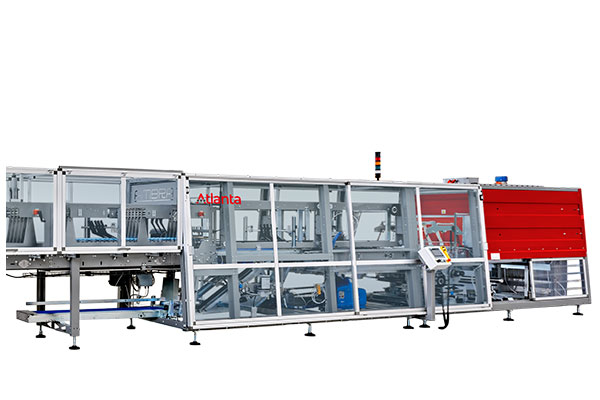

The modular structure of Atlanta’s shrink-wrap machines allows the installation of the feeding unit that is suited to your particular product, whether this is loose arriving in-line, on crossover infeed conveyor or at 90°.

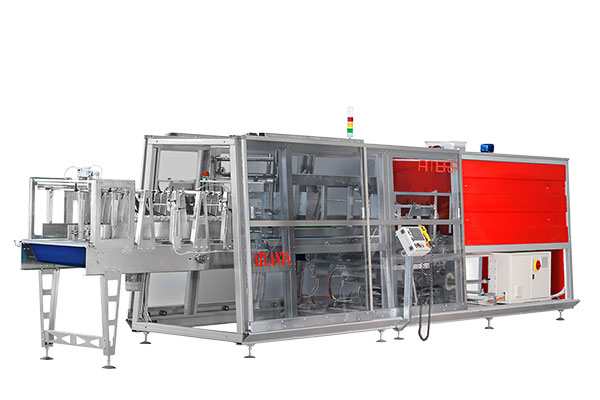

The Ambra Series is designed for modern production processes that require packaging several types of pack on a single production line, even with very different sized or irregularly shaped products.

The format changeover is quick and easy and usually without needing to replace parts and it meets the following requirements: film, only pad plus film, or tray plus film.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Depending on the chosen model, you can pack your products with film only, pad plus film, or pad or tray plus film.

For those in search of a reliable and versatile entry-level automatic shrink-wrap machine

Ambra is a series of automatic shrink-wrap machines for secondary packaging recommended for production of up to 30 packs per minute

Packaging: Film

Dimensions: 8,102 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 25, Double lane: 50, Triple lane: 75

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 8,102 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 30, Double lane: 60, Triple lane: 90

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 6,542 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 25

Feeding: In-line 4 channels, 90° optional, Anti-jamming unit only in-line

Separation: Base

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 6,542 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 30

Feeding: In-line 4 channels, 90° optional, Anti-jamming unit only in-line

Separation: Base

Oven: Heat-shrink tunnel

Packaging: Pad + Film

Dimensions: 8,102 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 25, Double lane (function can be activated in film only mode): 50, Triple lane (function can be activated in film only mode): 75

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad + Film

Dimensions: 8,102 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 30, Double lane (function can be activated in film only mode): 60 , Triple lane (function can be activated in film only mode): 90

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only function available as optional

Dimensions: 9,651 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 25, Double lane (function can be activated in film only mode): 50, Triple lane (function can be activated in film only mode): 75

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only function available as optional

Dimensions: 9,651 x 1,570 x 2,108 mm (LxWxH)

Speed packages/minute: Single lane: 30, Double lane (function can be activated in film only mode): 60 , Triple lane (function can be activated in film only mode): 90

Feeding: In-line 4 channels, Double and triple lane optional, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: only tray

Dimensions: 5990 x 1550 x 1995 mm (LxWxH)

Speed packages/minute: 25

Feeding: In-line 4 channels, 90° optional, Anti-jamming unit only in-line

Separation: Long crossbars

Pad – Tray Magazine: 500

Frame and mechanical parts without welding to ensure utmost efficiency and consistency of performance over time.

Each moving part is protected to ensure the safety of line operators.

Sliding safety guards allow the operator to have full view of the machine, the wide opening ensures easy access during maintenance and cleaning.

Machine designed to operate over three shifts, with low energy consumption and silently.

High efficiency heat-shrink tunnel even with several lanes in operation.

Touch screen panel with simple and intuitive interface: this allows the operator to quickly set all parameters.

Quick format changeover by means of the standard touch screen control panel; it normally does not require replacing parts.

Optional automatic format changeover.

High precision centring of the printed film also on several lanes.

Combined product presence check in the channels, both with feelers and with photocells.

Available in partial or full stainless steel versions.

Cutting blade length: 700 mm

Installed power: 45 kW – 50 kW

Voltage: 400V – 3 Phase / 50 Hz + N + G

Auxiliary voltage: 24V DC/AC

Electrical protection: IP54

Compressed air consumption: 100 NI/cycle at 6 bar

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Total weight: 3,300 kg – 4,000 kg

Product presence check: feelers + photocells

Machine colour: RAL 7037 (gray), RAL 3020 (red)

An extensive range of optionals to make this shrink-wrap machine perfect for your production line:

Automatic format changeover

Printed film: centring

Second reel holder

Double or triple lane for small formats

Adjustable feeding guides with handwheels

Manual or automatic centralized lubrication

Motorized crossover infeed conveyor

Photocells for product presence check after separation phase

Pneumatic motor to empty oven in case of power shut off

Electrical panel air conditioning

Partial stainless steel version

Customized RAL colour

Teleassistance

4.0 Industry

Watch the Ambra series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

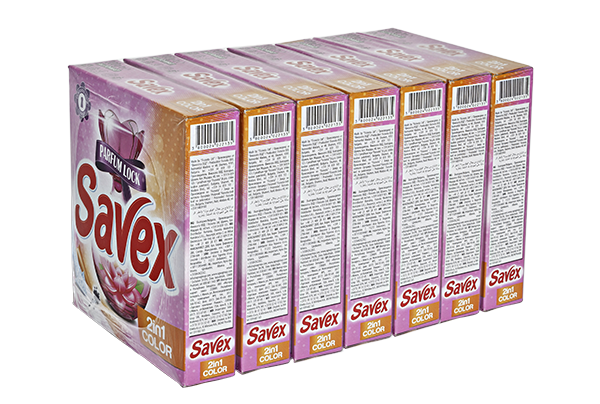

Washing powder boxes are an example of apparently easy to pack products.

In actual fact, this type of packaging requires experience to guarantee a continuous work flow in time because the base of these cases is irregular and the weight of their contents makes them unstable.

The Customer wanted to equip AMBRA SV with a series of optionals to have a top quality machine with minimum overall dimensions.

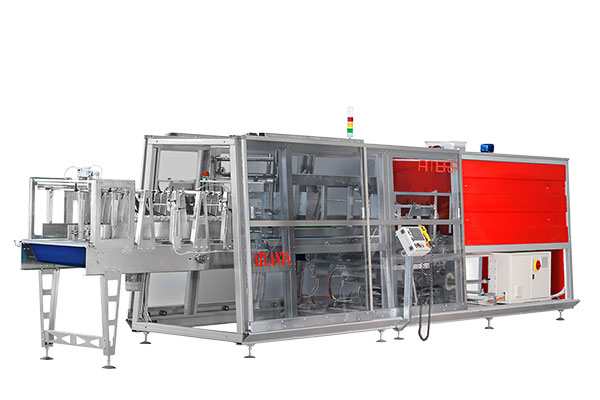

The versatility of the Ambra Series made it possible to use a single machine to pack 200 ml, 300 ml, 330 ml, 500 ml and 1000 ml PET bottles with quick format changeovers without needing to replace parts.

The customer picked Ambra M for the secondary packaging of its products because he needed to complete a line that was already up and running where there was little space available.

He therefore needed a very compact and reliable shrink-wrap machine, which would allow the product to arrive at 90 degrees.

Boasting a productivity of 1,500 packs/hour in just 654 cm, Ambra 90M was the natural choice.

We understand that each line has specific needs, therefore the models in the Ambra Series are designed to be easily implemented with tailored functions that meet all your needs.

POWERED BY

Atlanta S.p.A.

Via Europa n.13

40010 Sala Bolognese (Bo) Italy

T. +39 051 722792

SDI M5UXCR1

Tax code and VAT reg. no. 02144141203

Share capital € 1.000.000,00 i.v

REA 416021

Registration date REA: 09/02/2001