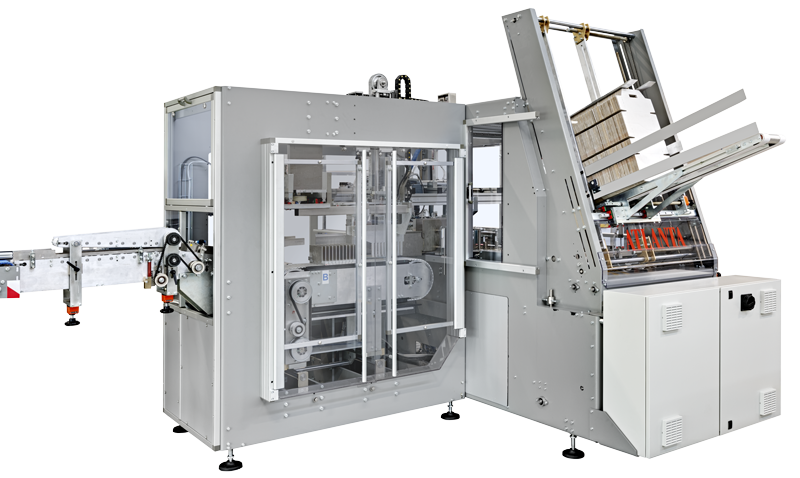

Wrap-around cartoning machine for products in flexible packs, stand-up pouches, bags, pouches, doypacks and products that need to be upright before being packed

The interchangeable feeding module makes it possible to manage noticeably different sized products on a single line, as well as easy and quick format changeover.

Feeding designed for stand-up pouches and products that arrive lying down on the belt.

The carton picking system with suction cups is designed for flat blanks – even if they are not perfectly flat – with a thickness of 2-5 mm.

The interchangeable feeding module speeds up the format changeover in the event of very different sized products.

Ergonomic and easy-to-use wrap around packaging machine with raised magazine for rapid blank refilling.

The wrap around unit forms both closed packs and open display packs for top qualityshelf products.

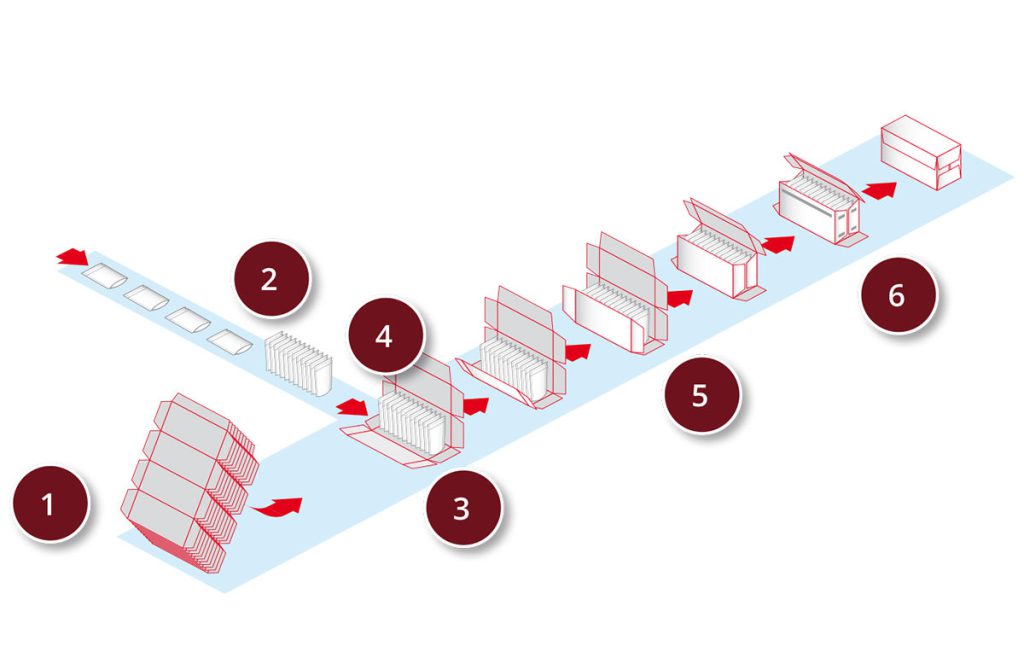

The product arrives lying down, the feeding unit places the product standing, grouping it according to the pre-set configuration and keeps it upright while an arm with suction cups picks the blank from the magazine and places it on the conveyor belt, where, in the meantime, the pusher has placed the product group, around which the box is formed.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Packaging: wrap-around

Dimensions: 4,675 x 4,318 x 2,500 mm (LxWxH)

Velocità: 15 cartons/minute

Feeding: In-line with compartments

Separation: Transfer unit

Magazine: Capacity 200, Possibility of extension 400 optional

Production speed: up to 15 cartons per minute

Blank thickness: 2 to 5 mm

Upper flap closure: internal

Installed power: 13 kW

Voltage: 400V – 3-Phase/50Hz + N + G

Electrical protection: IP54

Compressed air consumption: 400 NI/ciclo a 6 bar

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Total weight: 2,500 kg

Product presence check: feelers + photocells

Machine colour: RAL 7037 (gray)

Partial automatic format changeover

Complete compartment conveyor

Manual or automatic centralized lubrication

External upper flap closure

Customized RAL colour

Electrical panel air conditioning

Interface with host computer for data transfer

Teleassistance

Watch the Palladio series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

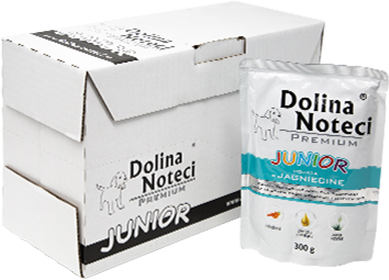

A well-known manufacturer of pet food, which packs its products in stand-up pouches, needed to complete its end of line with a cartoning machine capable of packing display boxes for shelf display.

The request envisaged several types of 10×1 packs with individual portion pouches of between 150 g and 300 g.