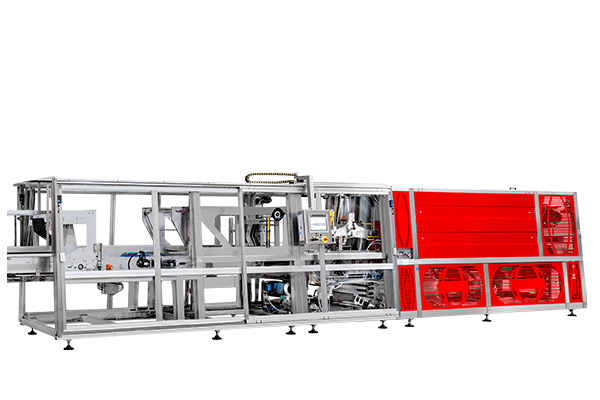

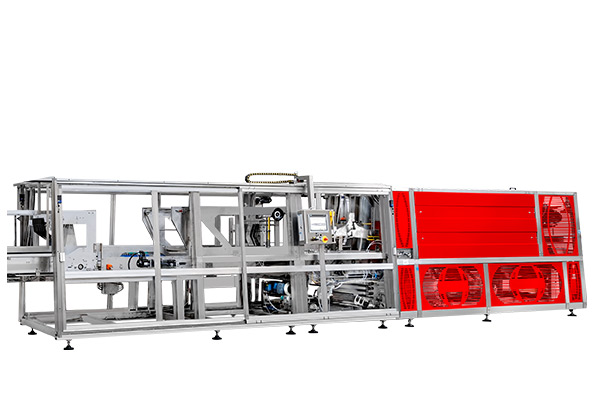

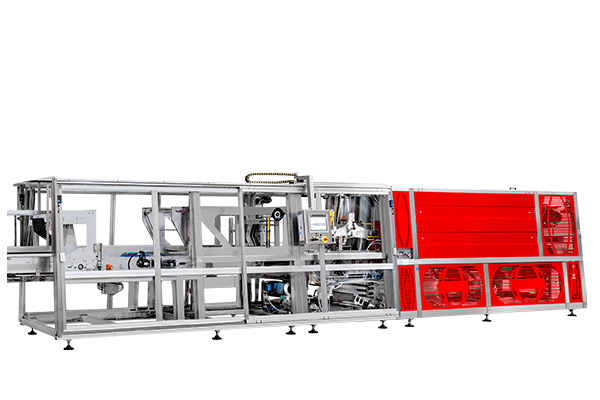

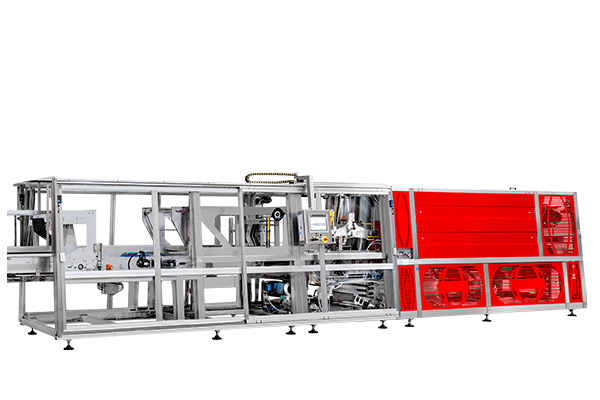

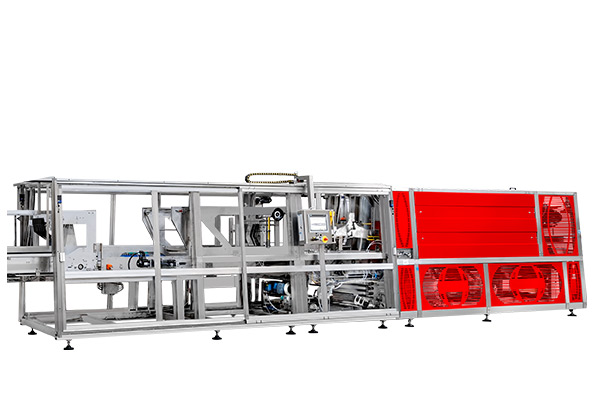

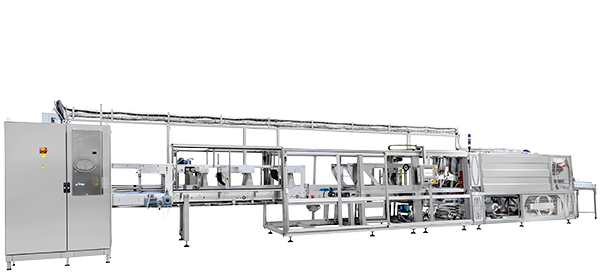

Automatic shrink wrap machines recommended for lines that require high speed. The folded sheet frame without welding, also available in the partial or full stainless steel version, makes these machines stable, flexible and easy to clean.

Packs loose or pre-bundled products.

Film cut with rotary blade driven by a brushless motor for perfect cutting at high speed.

The soft touch technology accompanies the product into the machine.

Adjustable air flow within the tunnel, for controlled heat shrinking according to the size of the pack.

Double reel holder as standard for greater production autonomy.

The soft touch pushing unit ensures that the accompanying crossbars do not damage the product when it comes into contact with them; the motor regulates the push to move both large and heavy products and small or fragile products in an optimal way.

To ensure greater speed, the Opale Cont versions use a feeding with continuous separation, controlled by one or more separately powered belts. An inverter controls the belts and groups the products without stopping their advancement along the line.

Designed to optimise production times, this automatic shrink-wrap machine has a double reel holder as standard, the magazine for pads and trays is easy to refill and capacious; the heat-shrink tunnel that can be inspected is fitted with a wide panel that opens.

The printed film centring guarantees top quality packs even with highly complex graphics and the film wrapping is controlled with a bar that can be adjusted according to the height of the product.

Built according to ergonomic criteria, all its parts are easy to access in order to minimise maintenance times. The line operator has a complete view of the machine’s activities thanks to transparent guards and visible mechanical parts.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Depending on the chosen model, you can pack your products with film only, pad plus film, or pad or tray plus film.

7 standard models and endless tailored solutions to guarantee maximum production efficiency

Packaging: Film

Dimensions: 8,338 x 1,570 x 2,200 mm (LxWxH)

Speed packages/minute: 40 Single lane

Feeding: In-line 4 channels, 90° optional

Separation: Base

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 9,849 x 1,547 x 2,074 mm (LxHxW)

Speed packages/minute: Single lane 45, Double lane 90, Triple lane 135

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Film or Pad + Film

Dimensions: 9,849 x 1,547 x 2,074 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane 90 and Triple lane 135 function can be activated in film only mode

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad and Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only function available as optional

Dimensions: 13,410 x 1,700 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane 90 and Triple lane 135 function can be activated in film only mode

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad and Tray Magazine: 500

Packaging: only Film

Dimensions: 11,350 x 1,600 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane 120, Triple lane 180

Feeding: In-line 4 channels, Double and Triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: Heat-shrink tunnel

Packaging: Pad + Film

Dimensions: 11,350 x 1,600 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane 120 and Triple lane 180 (function can be activated in film only mode)

Feeding: In-line 4 channels, Double and Triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only function available as optional

Dimensions: 11,350 x 1,600 x 2,200 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane 120 and Triple lane 180 function can be activated in film only mode

Feeding: In-line 4 channels, Double and Triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Soft touch technology for fragile packages: the movement of the crossbars accompanying the product ensures calibrated contact in order not to damage the products.

Rotating cut driven by brushless motor for a perfect cut even at high speeds.

Adjustable air flow within the tunnel, for controlled heat-shrinking according to the size of the package.

Heat-shrink tunnel that can be inspected: wide panel that can be opened to minimise maintenance time.

Double reel holder as standard for greater production autonomy.

Manuals and technical documentation available in the language of the country of installation (upon request).

Certifications: meeting the regulations of the target country.

Smart integration: Compatible with the most widespread enterprise management (ERP) and software protocols.

Designed for your product: the entire product path and its movement are optimised according to the samples you supply.

Cutting blade length: 700 mm

Installed power: 65 kW – 70 kW

Voltage: 400V – 3 Phase / 50 Hz + N + G

Auxiliary voltage: 24V DC/AC

Electrical protection: IP54

Compressed air consumption: 20 NI/cycle at 6 bar

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Total weight: 3,300 kg – 4,000 kg

Product presence check: feelers + photocells

Machine colour: RAL 7037 (gray), RAL 3020 (red)

Automatic format changeover

Double and triple lane

Printed film: centring

Adjustable feeding guides with handwheels

Manual or automatic centralized lubrication

Motorized crossover infeed conveyor

Photocells for product presence check after separation phase

Pneumatic motor to empty oven in case of power shut off

Partial stainless steel version

Customized RAL colour

4.0 Industry

Electrical panel air conditioning

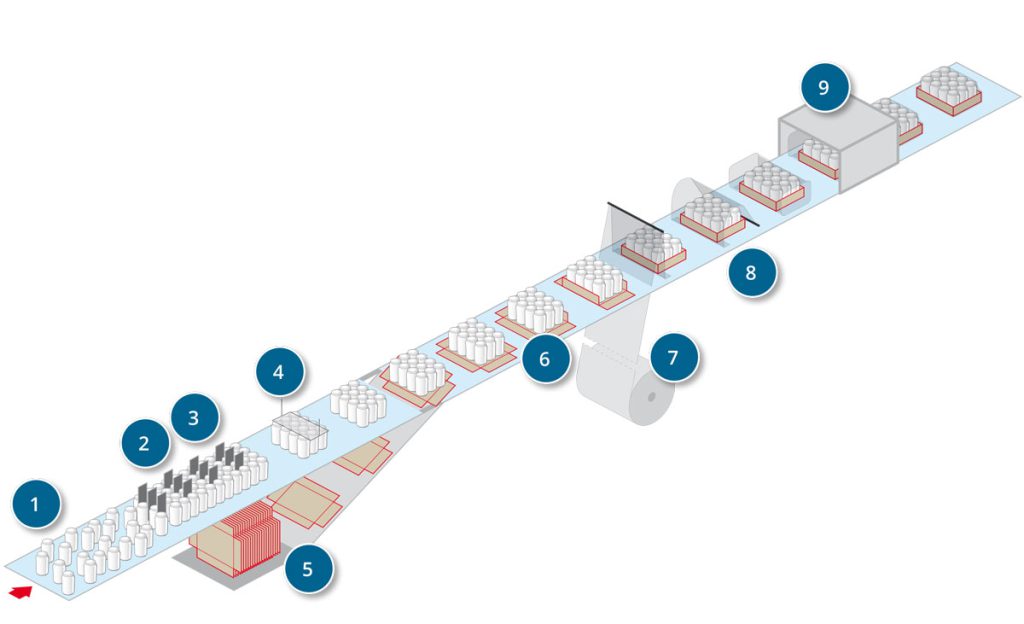

1 – Loose products feeding, arriving in-line, on crossover infeed conveyor, or at 90°.

2 – Pneumatic anti-jamming unit with oscillating separating bars for proper channelling of the product.

3 – Maximum accumulation sensor to check the incoming belt. Minimum accumulation sensor for each channel.

4 – Alternated separation without mechanical gears or continuous separation.

5 – High capacity blank magazine for pads and trays, located on the bottom, with easy access to be quickly refilled.

6 – Tray closed with glue points.

7 – Film feeding by means of a pair of rollers powered by a brushless motor.

8 – Neutral or printed film wrapping by means of a bar that can be adjusted according to the height of the product.

9 – High efficiency output heat-shrinking tunnel.

Watch the Opale series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Customer’s request:

stainless steel version with extended feeding, customised equipment and overhead cables.

We understand that each line has specific needs, therefore the models in the Opale Series are designed to be easily implemented with tailored functions that meet all your needs.

Customer’s request:

quick format changeover, controlled from the touch screen panel without changing parts, for multiple configurations, with or without tray, for PET bottles with the following formats: 0.25 L, 0.50 L, 0.75 L, 1 L, 1.5 L, 2 L, 5 L.