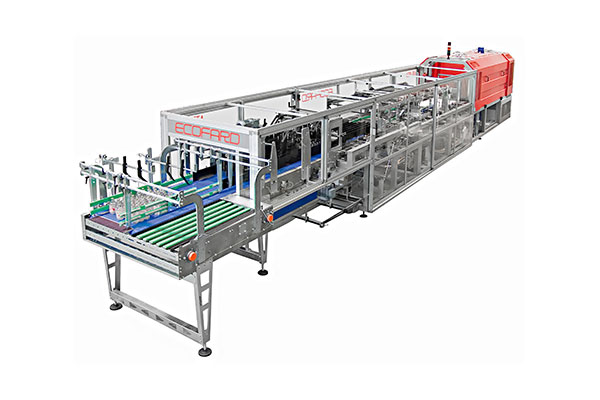

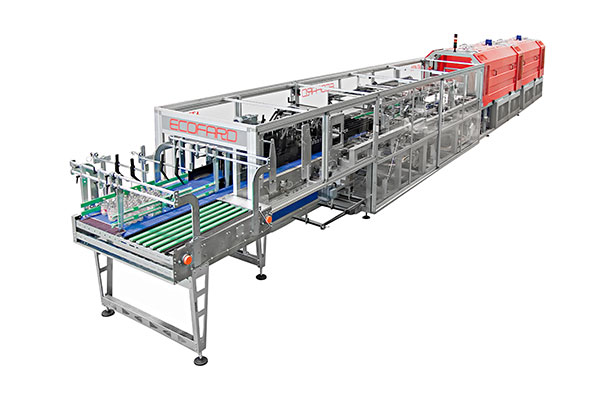

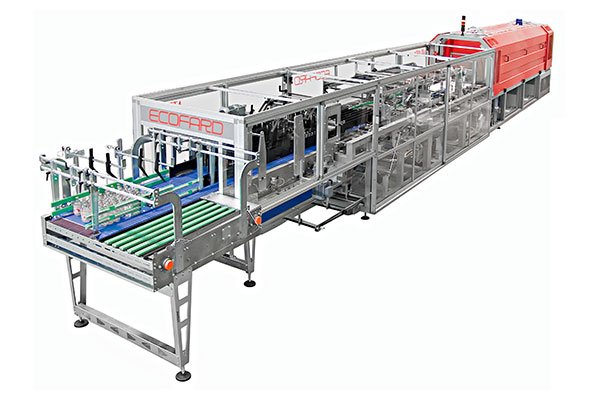

Top-of-the-range automatic end of line packaging machines which, in compact dimensions, guarantee high production speeds, quality packs even in double layer, flexibility of formats and easy use.

Packs boxes, tins, jars, cans, bottles, spray cans, bins, cases, trays, dispensers, bricks, whether loose or pre-bundled.

Top-of-the-range packaging machines for intensive high-speed production cycles.

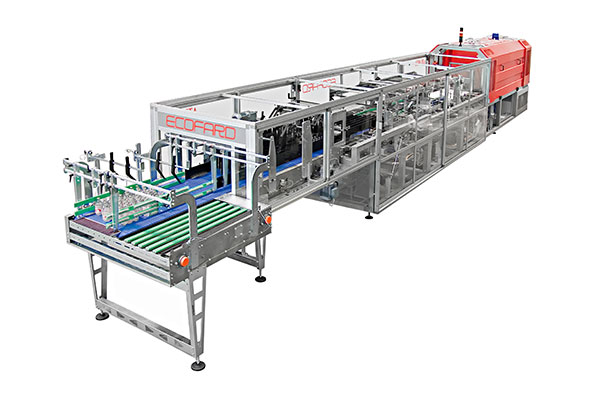

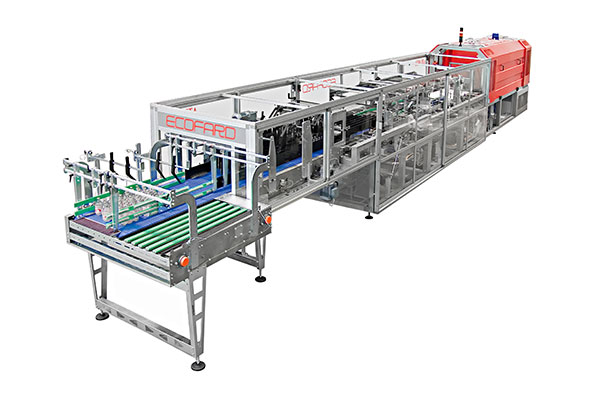

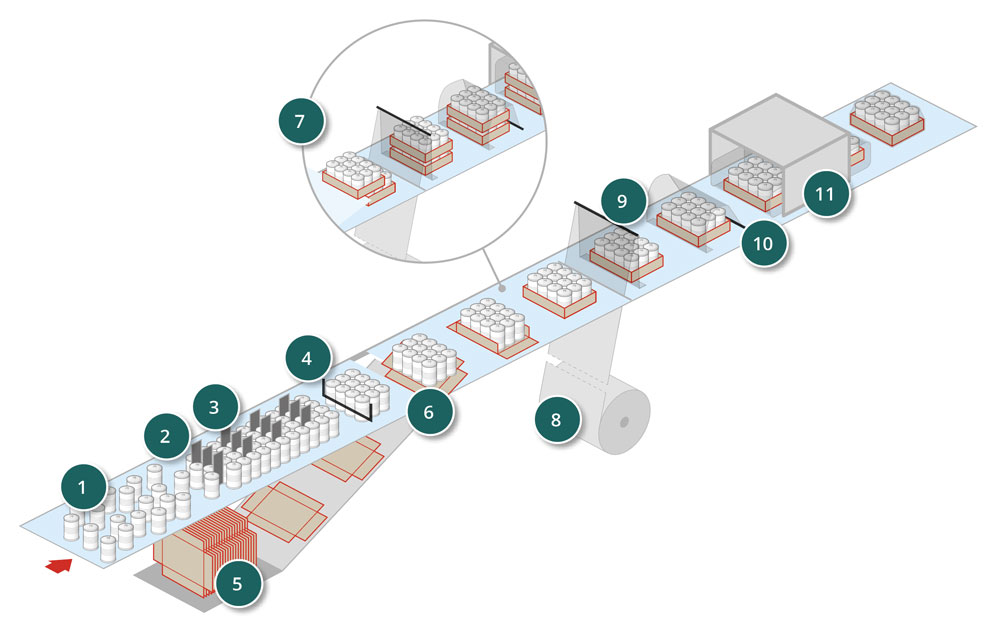

Ecofard DL is fitted with a wide double lane as standard to pack medium/large products and guarantee greater productivity.

Double layer option with precision stacker for “tray+tray” product stacking.

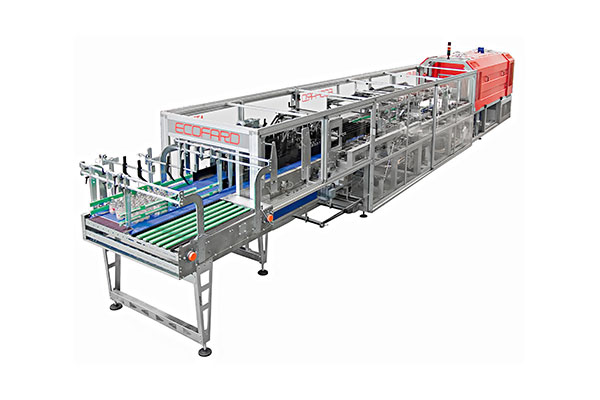

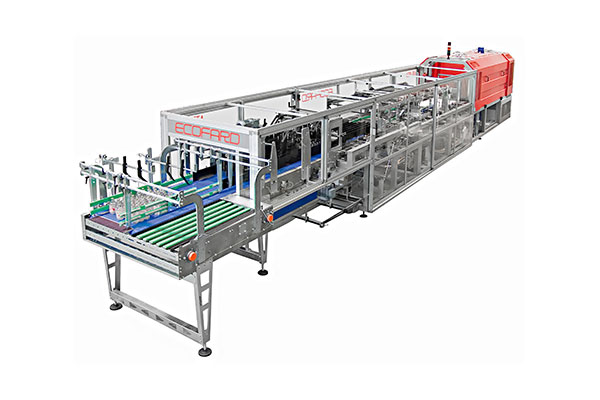

Ecofard series boasts high energy efficiency brushless and asynchronous motors, high-efficiency heat-shrink tunnel with infeed pre-chamber to prevent dissipation of heat and air flow control module to manage turbulence.

Double reel holder as standard for greater production autonomy (optional on Ecofard F, C, V).

Printed film centring for precise packaging even with highly complex graphics.

Designed to accommodate the demand for flexibility in high-speed production lines, the Ecofard series is an end of line packaging machine for bottles, jars, cases, bricks, vials and dispensers for the beverage, food, personal care and detergent sectors

The Ecofard Series is manufactured with excellent quality materials and components to keep constant performance over the years for production lines that work 7 days a week up to three shifts.

Ecofard has an optional film centring technology which, together with the rotary cutting and the film unwinding system powered by brushless motors, makes it possible to produce precise packs even with bundles that are particularly detailed.

The reel unwinding is controlled by a pneumatic brake that ensures proper film tension at any speed.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

Depending on the chosen model, you can pack your products with film only, pad plus film, or pad or tray plus film.

14 standard models and endless tailored solutions to guarantee maximum production efficiency

Packaging: Film

Dimensions: 7,460 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: 30 Single lane

Feeding: In-line 4 channels, 90° optional, Anti-jamming unit only in-line

Separation: Base

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 9,070 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 35, Double lane 70, Triple lane 105

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Film or Pad + Film

Dimensions: 9,070 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 35, Double lane (function can be activated in film only mode) 70 and Triple lane (function can be activated in film only mode) 105

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only and Double layer function available as optional.

Dimensions: 10,785 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 35, Double lane (function can be activated in film only mode) 70 and Triple lane (function can be activated in film only mode) 105

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: only Film

Dimensions: 10,100 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane: 90, Triple lane 135

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Pad + Film

Dimensions: 10,110 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane (function can be activated in film only mode) 90 and Triple lane (function can be activated in film only mode) 135

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only and Double layer function available as optional.

Dimensions: 11,820 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane (function can be activated in film only mode) 90 and Triple lane (function can be activated in film only mode) 135

Feeding: In-line 4 channels, 90° optional, Double and Triple lane optional, Anti-jamming unit only in-line

Separation: Long crossbars

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Film

Wide double track for medium/large products.

Dimensions: 10,850 x 1,600 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 45, Double lane 90, Triple lane 135

Feeding: In-line 8 channels, Doppia pista di serie, Triple lane optional, Anti-jamming unit.

Separation: Long crossbars

Oven: Heat-shrink tunnel

Packaging: Film

Dimensions: 11,120 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane 120, Triple lane 180

Feeding: In-line 4 channels, Double lane and Triple lane optional, Anti-jamming unit.

Separation: Continuous

Oven: Heat-shrink tunnel

Packaging: Pad + Film

Dimensions: 11,120 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane (function can be activated in film only mode) 120, Triple lane (function can be activated in film only mode) 180

Feeding: In-line 4 channels, Double lane and Triple lane optional, Anti-jamming unit.

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film; Film only and Double layer function available as optional

Dimensions: 12,835 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 60, Double lane (function can be activated in film only mode) 120, Triple lane (function can be activated in film only mode) 180

Feeding: In-line 4 channels, Double lane and Triple lane optional; Anti-jamming unit.

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad + Film

Dimensions: 13,680 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 80, Double lane (function can be activated in film only mode) 160, Triple lane (function can be activated in film only mode) 240

Feeding: In-line 4 channels, Double lane and Triple lane optional, Anti-jamming unit.

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Packaging: Pad or Tray + Film

Dimensions: 15,900 x 1,360 x 2,246 mm (LxWxH)

Speed packages/minute: Single lane 80, Double lane (function can be activated in film only mode) 160, Triple lane (function can be activated in film only mode) 240

Feeding: In-line 4 channels, Double lane and Triple lane optional, Anti-jamming unit.

Separation: Continuous

Oven: Heat-shrink tunnel

Pad – Tray Magazine: 500

Double layer: precision stacker to overlay “tray+tray” products.

Wide double track for medium/large products.

Soft touch technology for fragile packs: the movement of the crossbars accompanying the product ensures controlled contact to avoid damaging the products.

Rotating cut driven by brushless motor for a perfect cut even at high speeds.

Double reel holder as standard for greater production autonomy.

Adjustable air flow within the tunnel, for controlled heat-shrinking according to the size of the package.

Heat-shrink tunnel that can be inspected: wide panel that can be opened to minimise maintenance time.

Manuals and technical documentation available in the language of the country of installation (upon request).

Certifications: meeting the regulations of the target country.

Smart integration: Compatible with the most widespread enterprise management (ERP) and software protocols.

Designed for your product: the entire product path and its movement are optimised according to the samples you supply.

Cutting blade length: 650 mm

Installed power: 45 kW to 100 kW

Voltage: 400V – 3 Phase / 50 Hz + N + G

Electrical protection: IP54

Compressed air consumption: 20 Nl/cycle at 6 bar

Total weight: 4,000 Kg- 5,300 Kg

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Product presence check: feelers + photocells

Machine colour: RAL 7037 (gray), RAL 3020 (red)

Automatic format changeover

Double layer stacker

Double and triple lane

Printed film: centring

Automatic reel replacement

Adjustable feeding guides with handwheels

Manual or automatic centralized lubrication

Motorized crossover infeed conveyor

Photocells for product presence check after separation phase

Pneumatic motor to empty oven in case of power shut off

Partial stainless steel version

Customized RAL colour

4.0 Industry

Electrical panel air conditioning

Teleassistance

Watch the Ecofard series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

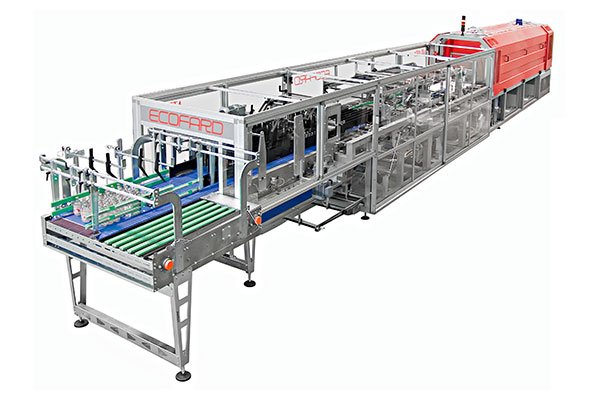

Can 15 different types of containers be packed with a single shrink-wrap machine?

That’s what a glass container manufacturer asked us, with the intention of automating their line used for glass jars ranging between 61 mm and 308 mm in height and a capacity of between 106 cc to 1 litre. Ecofard was the chosen solution.