Designed for high-speed production lines, Aragon is the continuous movement shrink-wrap packaging machine with film feeder for the beverage industry end of line.

Such high speeds of production require maximum precision from every component, which is why Aragon boasts state-of-the-art mechanics, a product accompanying system that keeps the bottles stable even at top speed and is fitted with carbon fibre wrapping bars providing high rigidity and less weight, generating greater precision during the wrapping phase.

Speed, control and simple use are the distinguishing features of this automatic machine that requires minimum maintenance and is equipped with all the optionals to automate lubrication and reel replacement operations.

The entire packaging cycle is monitored by a series of mechanical and optic sensors that control the product in transit.

Heat-shrink tunnel with high-efficiency separated chambers to decrease energy consumption considerably.

Dedicated adjustable air flow partitions for each lane.

Pneumatic motor to empty oven in case of power shut off.

Sliding safety guards leave the operating areas completely free.

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.

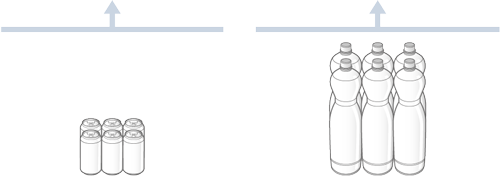

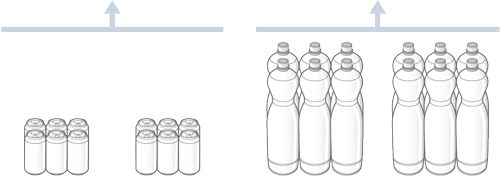

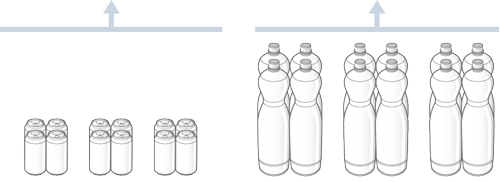

Aragon is the continuous motion automatic shrink film packaging machine with film launch for lines that require a speed of up to 100 packs per minute in single lane and 300 packs per minute in triple lane.

Packaging: film

Dimensions: 18.029 x 1.653 x 2.105 mm (LxPxH)

Speed packages / minute: Single lane: 100, Double lane: 200, Triple lane: 300

Feeding: In-line 4 channels, Double and triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: shrink tunnel

Fans: 4

Packaging: film

Dimensions: 16.050 x 1.653 x 2.189 mm (LxPxH)

Speed packages / minute: Single lane: 55, Double lane: 110, Triple lane: 165

Feeding: In-line 4 channels, Double and triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: shrink tunnel

Fans: 5

Packaging: film

Dimensions: 18,029 x 1,653 x 2,105 mm (LxWxH)

Speed packages / minute: Single lane: 100, Double lane: 200, Triple lane: 300

Feeding:In-line 4 channels, Double lane and Triple lane optional, Anti-jamming unit

Separation: Continuous

Oven: shrink tunnel

Production speed: Up to 300 bundles/minute with triple lane

Film maximum width: 950 mm

Installed power: 96 kW

Voltage: 400V – 3 Phase / 50 Hz + N + G

Electrical protection: IP54

Compressed air consumption: 15 Nl/cycle at 6 bar

Operating temperature: min +5°C – max +40°C

Relative humidity: max 70%

Total weight:6,000 Kg

Machine colour: RAL 7037 (gray), RAL 3020 (red)

Printed film: centring

Automatic reel change with external film insertion

All machine adjustments can be performed electronically

Centralized lubrication

Modem for remote support and interface with central data collection system

Double or triple lane

Watch the Aragon series in action

If you need more detailed information, our product managers are ready and willing to help.

We’ll answer your queries promptly.